REVERSE ENGINEERING

Reverse engineering is a method for obtaining the design related information about a product in order to reproduce or to develop it when the product is physically available but blueprint of its original design is lacked.

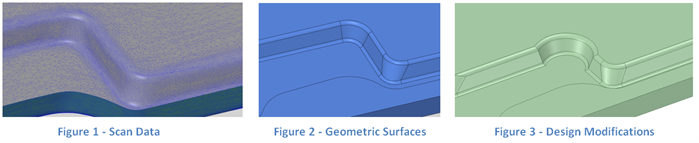

Numerical data is collected by getting the product scanned via 3D optical measurement systems. This data is defined as polygon mesh (stl) data. CAD data of the product is obtained through a delicate engineering work on the polygon mesh data by the help of necessary reverse engineering software.

- The producer lacks the CAD data of the product that s/he will produce;

- The existing cad model is not suitable for changes and reconfigurations;

- The existing CAD model is not suitable for modern production technologies;

- Rival products being compared numerically/measurementally;

- A product’s mold is finalized manually so the producer lacks CAD data for production;

- Solely a misshaped part of a mold has to be fixed.

3D4U Technology serves you with the best applications of reverse engineering processes with its experienced specialists in various application and material types such as casting, plastic injection etc.