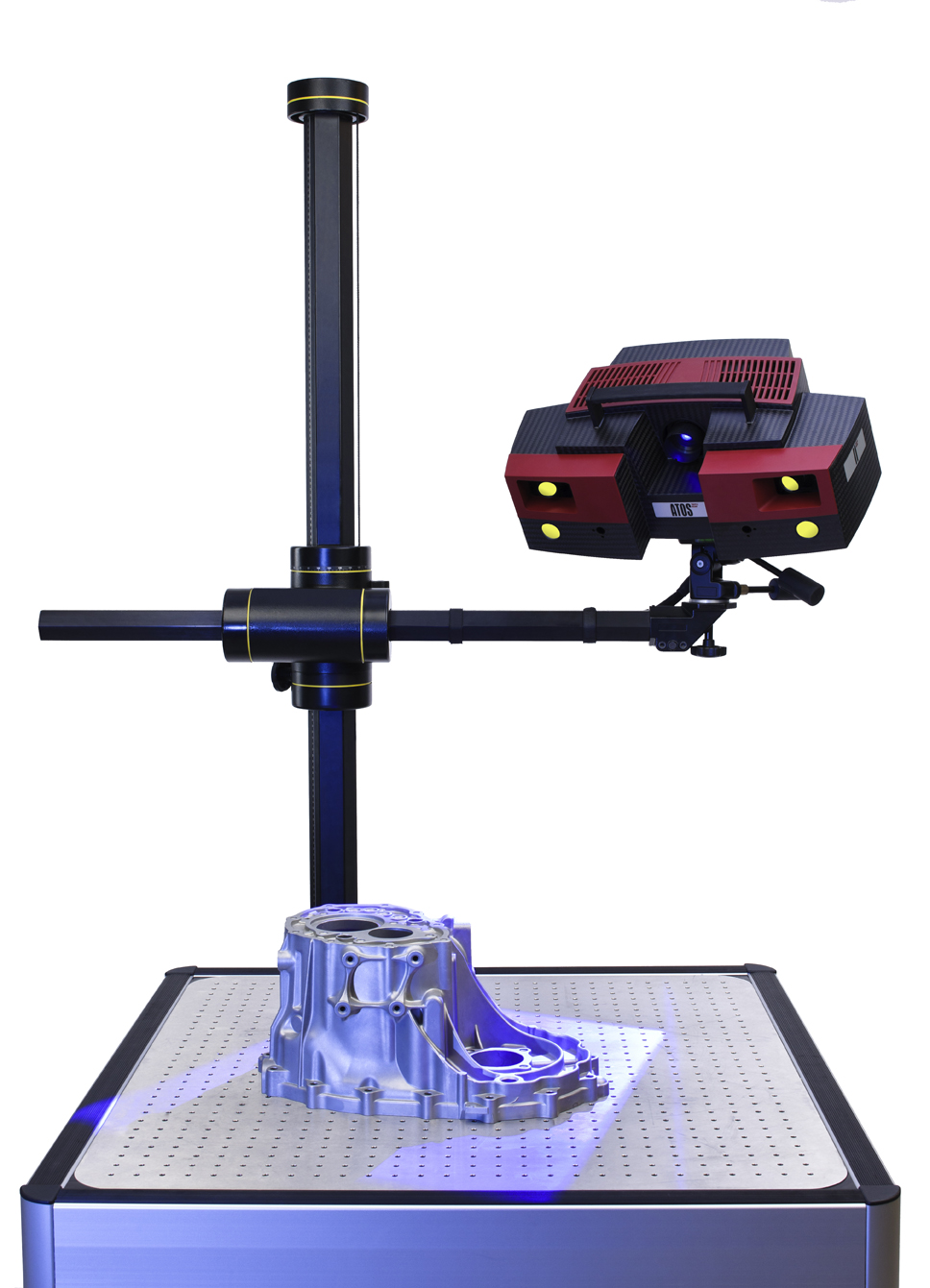

ATOS TRIPLE SCAN

3D COORDINATE MEASUREMENTThe ATOS Triple Scan uses a specially developed measuring and projection technology from GOM. Using this brand new technology the ATOS Triple Scan produces a high accuracy and improved measurement of shiny surface, complete data on complex components with deep pockets or fine edges such as turbine blades, reducing the number of individual scans and resulting in a simple handling.

Blue Light Technology The ATOS Triple Scan is also equipped with blue light technology. The narrowband blue light enables precise measurements to be carried out independently of environmental lighting conditions.

High Resolution 3D Scanner from small to large

ATOS uses high resolution measuring cameras with up to 16 megapixel resolution and specially developed optics for precise measurement.

The accuracy, measurement resolution and measuring area are completely adaptable to the application requirements. This allows for the highest resolution for highly detailed, small parts with measuring volumes down to 38mm, or for extremely fast digitizing of large objects with measuring volumes up to 2m.

This flexibility allows measurement of a large part spectrum with the same sensor head, and when used in combination with TRITOP, the ATOS System is capable of scanning parts of over 30m with a high local resolution.

Industrial advantages for industrial processes The ATOS 3D Digitizer is an accurate and cost-effective solution in a number of different application areas including:

- Quality Control

- Reverse Engineering

- Rapid Prototyping

- Rapid Milling

- Digital Mock-Up

ATOS 3D Digitizers have been produced and constantly developed since 1995 and with more than 2500 installations in measurement and analysis rooms as well as factory and production halls worldwide, the ATOS has been for a long time an accepted measurement method beside the mechanical measurement machines.

The ATOS sensor combines high data quality in short measurement time with flexibility and stability for industrial environments.

The ultimate combination of optical and tactile measurement

The GOM Touch Probe combines full-field and touch probe 3D measurement. The GOM Touch Probe allows quick measurement in difficult to access areas, comparison directly to CAD, measurement of primitives, quick measurement of individual points and online alignment.

ATOS and Touch Probe measurements are carried out with one system and are evaluated with one software package. No extra hardware or tracker is required, enabling quick measurement procedures and easy interchange between surface and single point measurement and analysis.

The GOM Touch Probe combines full-field and touch probe 3D measurement. The GOM Touch Probe allows quick measurement in difficult to access areas, comparison directly to CAD, measurement of primitives, quick measurement of individual points and online alignment.

ATOS and Touch Probe measurements are carried out with one system and are evaluated with one software package. No extra hardware or tracker is required, enabling quick measurement procedures and easy interchange between surface and single point measurement and analysis.

Read more about the GOM Touch Probe.